Resources

- Home

- Resources

Industry Qualifications

Leading the development of International Standard ISO 20438:2017 Ships and Marine Technology-Offshore Mooring Chains

Equipments and Plants

Jingjiang Plant

Headquarters of ASAC group Established 1981 in Jiangsu Province

Anchor chains, mooring chains and accessories manufacturing

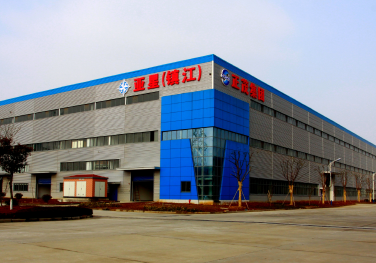

Zhenjiang Plant

Established 2006 in Jiangsu Province

Anchor chains, mooring chains and accessories manufacturing

Maximum size of chain: 240mm (Diameter)

Ma’anshan Plant

Established 2010 in Anhui Province

Anchor chains, accessories manufacturing

Chongqing Plant

Established 2023 in Sichuan Province

It mainly produces various marine anchors, engineering structure anchors and various steel castings.

Annual production capacity : 50,000 tons.

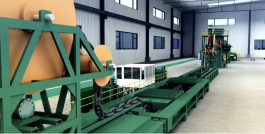

ASAC is equipped with world class manufacturing and testing equipment. This includes integrated core processes, R&D capability in anchor chain manufacturing and heat treatment ability. Heat treatment capabilities includes single-line heat treatment furnaces, line heat insulation devices, fully-automatic continuous anchor chain heat treatment furnaces. Other capabilities includes fully-automated anchor chain manufacturing production lines, 4000-ton tensile testing machine, flash welding control systems and various precision intactness testing equipment.

Anchor Chain Manufacturing Line

4000-Ton Tensile

Testing Machine

1000-Ton Fatigue

Testing Equipment

Heat Treatment

Furnaces

Chain Manufacturing Process

1. Bar cutting

2. Heating

3. Bending

4. Flash Butt Welding

5. Trimming

6. Shaping

7. Heat Treatment

8. Proof Testing

9. Shot Blasting

10. NDT

11. Delivering

Technology Research and Development

ASAC integrates design, R&D, manufacturing and service as a professional mooring chain and accessories vendor. To satisfy the different requirements for chain products from different clients, ASAC carried out extensive research in various parameters such as fatigue, corrosion, stress corrosion, hydrogen embrittlement and abrasion.

ASAC is then able to provide precise solutions to create greater value for users through material design, structural optimization, process research and surface treatment.

ASAC proudly owns the rights to multiple intellectual properties and invention patents for its products and technologies.

Fatigue Test Cases

ASAC carried out fatigue tests on the different grades of mooring chains developed by them using both 1000-ton and 400-ton fatigue testing machines. Results shows that fatigue curves of ASAC mooring chain products were more than twice the average life span of other mooring chain products in the market.

Anti-Corrosion Test Cases

After experimenting with different anti-corrosion solutions and performance tests, ASAC decided to apply heavy-duty anti-corrosion graphene coatings on its mooring chains for corrosion protection. It was found that the anti-corrosion were effective and at the same time, ensuring challenges faced during construction and overall costs reduced for our clients.

Hydrogen Embrittlement Test

Our R&D collaboration with steel mills results in the improvement of resistance against embrittlement of high-grade mooring chains. This effectively reduce hydrogen embrittlement on the chains which benefitted our clients who use these chains regularly on rigs and harsh environments.

Global Network